Product Description The heating way for the cleaning liquid is auto-heating. The operating principle: Set the cleaning temperature through the temperature

controller to control the steam control valve`s opening frequency to limit the steam amount making the cleaning liquid keep at needed

temperature. All the tanks liquid level in the CIP system adopt the auto-alarm. It will be increased the concentrated acid and alkali through

manually way when the cleaning liquid concentration reduced. The cleaning process transforming should be operated by the manually to

change some relevant pipelines and valves. Workers should increase the water-when the tank lack of water.

Technical Parameters

| Tank Size | 1000L-50000L | |||||

| CIP tank type | Alcal tank, acid tank, hot water, chean water tank, water recycle tank | |||||

| Cleaning recycles | Single circuit, double circuits, three circults, four circults. | |||||

| Heating method | Coll pipes inside, plate, tubular | |||||

| Automatic types and charastics | Full automatic | 1, Flow rate auto conrtol; 2, Temperature auto contral; 3, Auto compensate the cip liguld level; 4, Auto compensate the liquid concentrate; 5, Cleaning liquides auto transter; 6, Auto alarm. | ||||

| Semi-automiatic control | 1, Terrgerature auto control. 2, Electrical control with manual operate the other matters. | |||||

| Manual control | > Manual oprate on the cleaning process | |||||

KEAN has the highly professional packaging services and expertise to meet your most demanding packaging needs, aiming to bring your products to your location in less time and with higher quality.

FAQ

1. Is your company a factory or trading company?

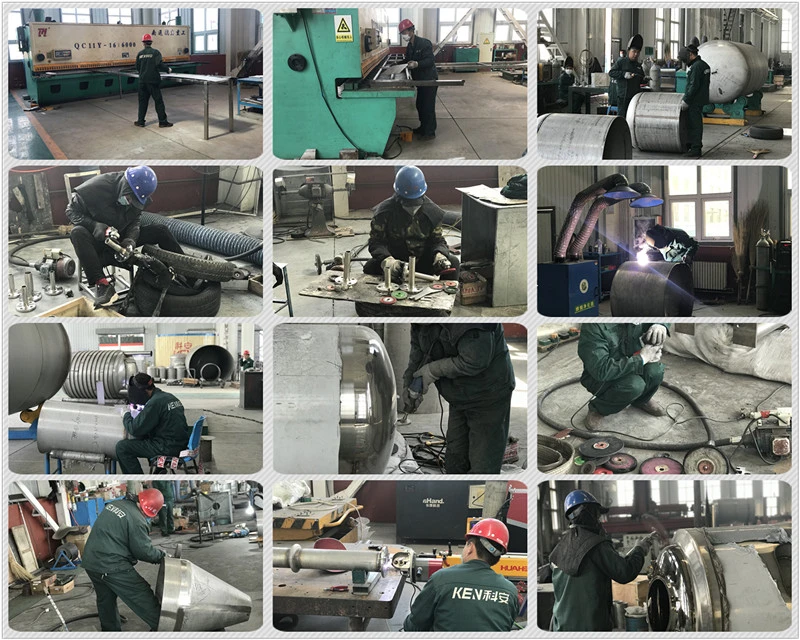

KEAN is a highly professional manufacturing entity focusing on fabricating pressure vessel and tanks, integrated bioengineering fermentation systems, cell culture systems, large infusion systems, fluid handling system, CIP/SIP systems.

2. Can you product as specific size?

Definitely we can. Our products are customized as per your requirements.

3. Can I have samples to test?

Yes, we are pleased to supply samples test report issued by renowned authority and ensure quality. Our products are fabricated stringently in compliant with ISO, ASME BPE, cGMP international codes.

4. Do you have any MQQ limitation?

Our MQQ is 1 PC to supply new customers.

5. How long is the lead time?

Normally it takes 5-6 weeks for tanks, and 7-10 weeks for integrate modular systems.

6. Do you provide after-sales service?

Yes, we are committed to offering highly professional and real-time after-sales service. We have many professional and dedicated engineers available ensuring a holistic service to our highly-respected customers.

Contact us for more information.

Abby

KEAN ZhuoLu Technical Equipment Co.,ltd

http://kean-z.en.made-in-china.com